EV Charger

- Home

- ENERGY MANAGEMENT

- EV Charger

Efficient charging and intelligent management: With the popularization of electric vehicles, we are leading the future of charging technology. Our current sensor is not only the core component of the charger, but also the key to efficient charging and intelligent management. Let’s explore the driving forces of the future together.

The main technical applications of current sensors in electric vehicle chargers:

- Current measurement and monitoring: The current sensor can measure the current in the electric vehicle charger in real time and accurately by using technologies such as Hall effect. This provides basic data for the charging process, ensuring that the charger can be properly controlled according to current requirements.

- Charging power control: By measuring the current through a current sensor, the charger can calculate real-time power. This helps to achieve precise control over the charging process of electric vehicles to meet user needs and grid conditions.

- Current regulation and protection: Current sensors can be used to regulate the current, ensuring the appropriate current level is maintained between the charger and the electric vehicle. At the same time, current sensors can monitor current anomalies, trigger protection mechanisms, and avoid damage to equipment and electric vehicles caused by overcurrent.

- Safety protection: The current sensor can also monitor the heat generated by the current in the charger, trigger the overheating protection mechanism, prevent equipment overheating, and ensure safe charging.

- Current isolation technology: The current sensor using magnetic isolation technology ensures effective isolation between the main and secondary circuits, improves system safety and stability, and prevents electrical isolation issues.

- Current data recording and reporting: Current sensors can store current data during the charging process for subsequent data analysis and report generation. This is of great significance for evaluating charger performance and electric vehicle charging habits.

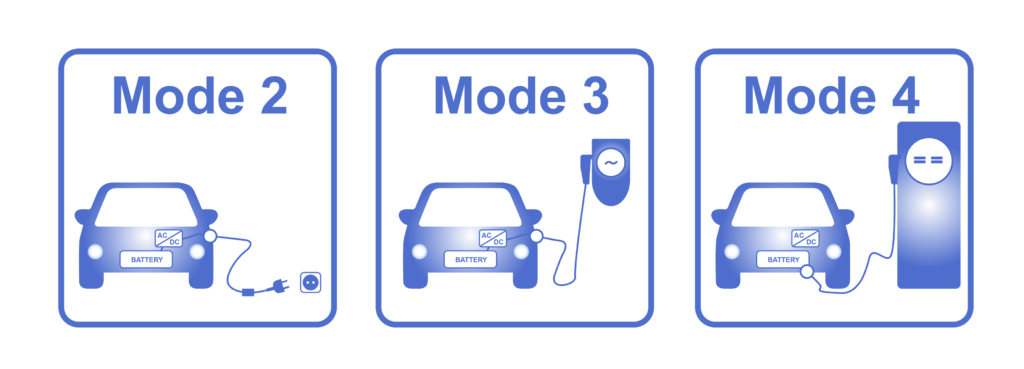

Typical application examples: EV Charging

- Mode 2

AC Charging Mode 2 is a basic home charging method where an electric vehicle is connected to a standard power outlet using a charging cable and a portable charger.

- Mode 3

AC Fast Charging Technology Mode 3 is a high-speed charging mode that typically requires specialized charging equipment. It is commonly found at public charging stations and provides a faster AC charging rate compared to Mode 2.

- Mode 4

DC Fast Charging Mode 4 is a rapid charging technology for electric vehicles. It utilizes a direct current power source to deliver high-power charging, often employed at fast-charging stations located in places like highway rest areas.

Our products:

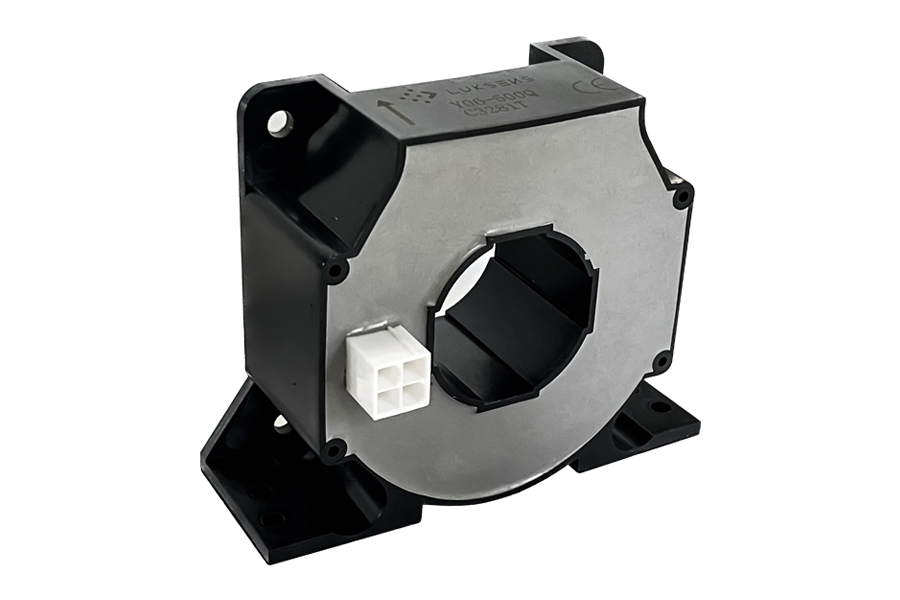

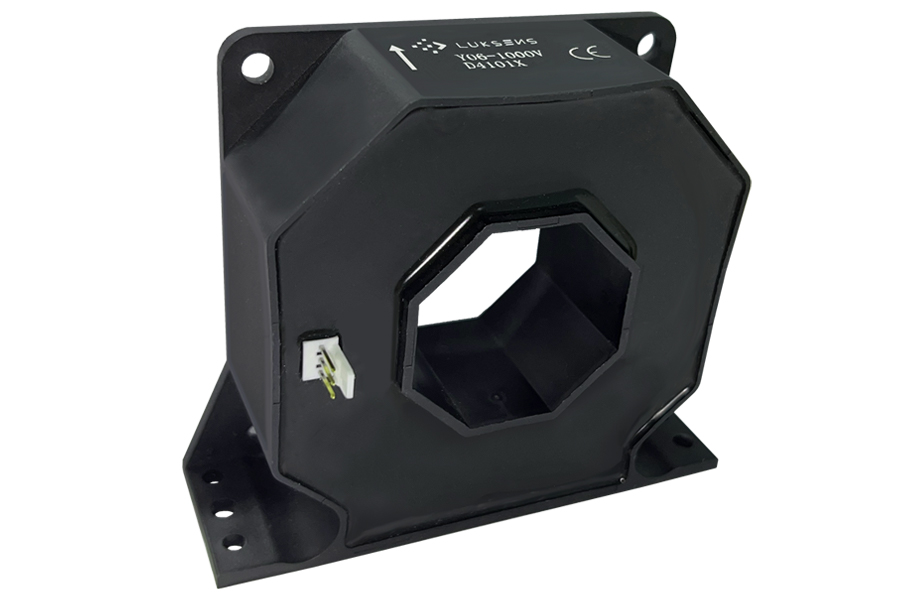

- Current transducer based on magnetic compensation principle

- Used for measuring DC, AC, or pulse currents and their combinations

- Using galvanic isolation technology to separate primary and secondary circuits

- Max. measuring range ±150A (DC or AC peak)

- High frequency bandwidth 100kHz

- Fast response 0.5μs

- Max. measuring range ±200A (DC or AC peak)

- Nearly zero magnetic hysteresis

- Fast response < 0.5μs

- High frequency bandwidth 100kHz

- Max. measuring range ±200A (DC or AC peak)

- Nearly zero magnetic hysteresis

- Fast response < 1μs

- High frequency bandwidth 100kHz

- Max. measuring range ±212A (DC or AC peak)

- Nearly zero magnetic hysteresis

- Fast response <0.5μs

- High frequency bandwidth 100kHz

- Max. measuring range ±150A (DC or AC peak)

- Nearly zero magnetic hysteresis

- Fast response <1μs

- High frequency bandwidth 200kHz

- Max. measuring range ±300A (DC or AC peak)

- Nearly zero magnetic hysteresis

- Fast response <1μs

- High frequency bandwidth 100kHz

- Max. measuring range ±800A (DC or AC peak)

- Nearly zero magnetic hysteresis

- High frequency bandwidth 100kHz

- Fast response <1μs

- Excellent current overload capacity

- Max. measuring range ±1500A (DC or AC peak)

- Nearly zero magnetic hysteresis

- Panel mounting

- Fastresponse<1μs

- Very low offset drift

- Max. measuring range ±150A (DC or AC peak)

- High frequency bandwidth 300kHz

- Compact size for PCB mount

- Rapid response, minimal noise output

- Superior temperature stability and linearity

- No insertion losses

- High immunity from external interference

- Nearly zero offset voltage

- High ESD sensitivity (Human Body Model) 4KV

- Max. measuring range ±270A (DC or AC peak)

- Compact size for PCB mount

- Unipolar power supply

- Very low offset voltage

- Fastresponse1μs

- High frequency bandwidth

- Nearly zero offset voltage