Latest Products

N502NEP Close-Loop current sensor

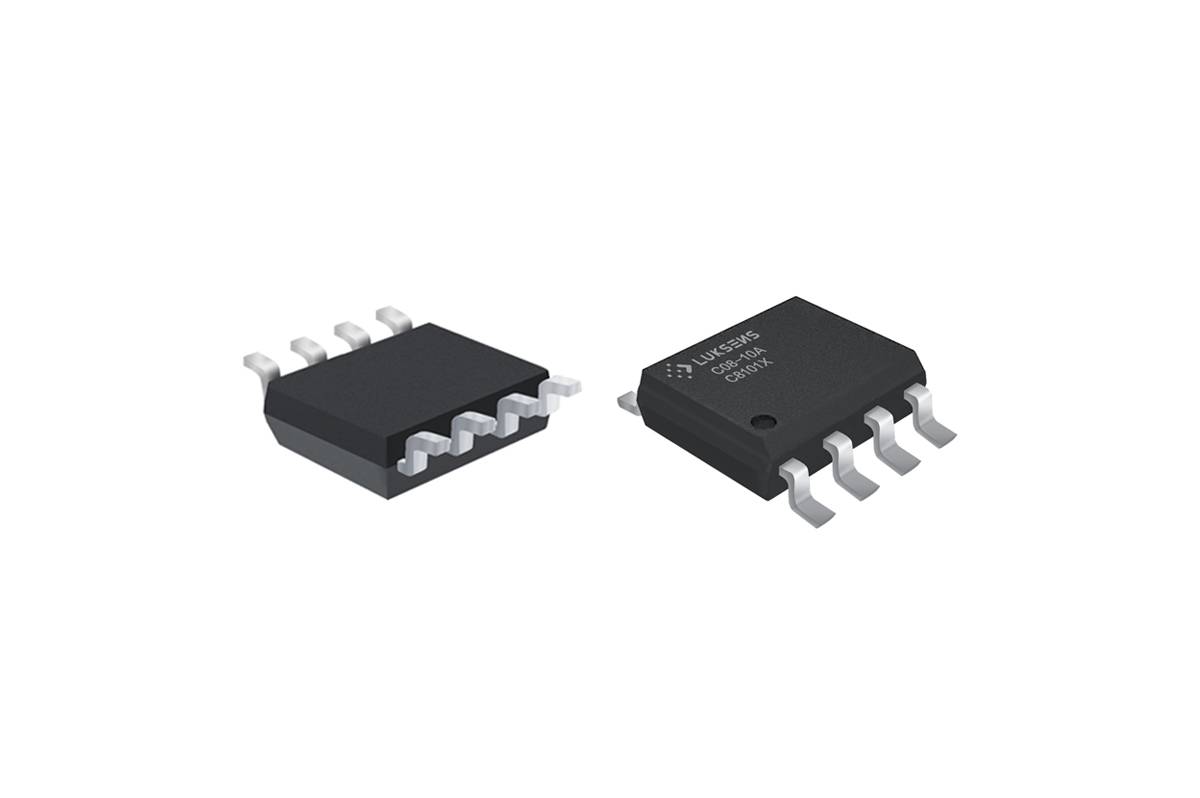

C08-10A Open-Loop current sensor

LF03-150 fluxgate current sensor

N2002P Close-Loop current sensor

C08-50A33 Open-Loop current sensor

C08-20A33 Open-Loop current sensor

C05-XXA33 series Open-Loop current sensor

C08-30A33U Open-Loop current sensor

C08-20A Open-Loop current sensor

CD570 DC Energy Meter

AC5 series Open-Loop current sensor

FAQs

The Hall Effect is the presence of a voltage when an external, perpendicular magnetic field is applied to a current carrying conductor. The conductor, or the Hall Element, is biased with a constant current. As magnetic field changes, a change in voltage across the hall element occurs. This voltage can then be amplified and conditioned to provide an output that is related to the magnetic field. Using this principle, magnetic field can be concentrated perpendicular to the hall element using integrated packaging, ferromagnetic cores, or coreless busbars. There are many current transducer manufacturers using this principle, as Hall effect current sensors have the advantage of inherent isolation, low power loss, and stability across temperature while providing an analog output voltage that can be monitored by a micro-controller. And it is what we provide as professional current transducer manufacturer.

There are different current sensors in the market, provided by currenr sensor suppliers. Basically every shunt solution can be replaced with an integrated Hall-effect sensor, simply by routing the current traces through the integrated current sensor rather than through an external shunt. The few shunt solutions that may not be practical for integrating Hall-effect sensors include ultra-low current resolution (in uA) or ultra-high speed (>1Mhz).

The main benefits of switching from a shunt solution to an integrated Hall-effect solution are increased isolation, reduced layout size, and reduced design complexity. The common-mode voltage of most shunt solutions cannot exceed 100 V without using an isolation amplifier that requires an external isolation circuit. Compare this to Hall-effect current sensors, which provide inherent isolation from the current path to the signal pins. Switching to Hall-effect sensors also eliminates the need for external shunts and input filtering. This reduces layout space and design complexity. If you are interest, feel free to email us. We can definitely provide you the solution as professional currenr sensor supplier.

Parts can be proportional or non-proportional. The ratio indicates that the device sensitivity is proportional to the device supply voltage VCC. Additionally, the device’s output at 0 A, also referred to as V IOUT(Q), is nominally equal to vcc /2. The VIOUT(Q) and sensitivity values for non-ratiometric devices are stable over changes in VCC over the specified input voltage range. The ratio method is useful when the sensor input voltage is on the same line as the ADC reference voltage. Non-proportional components are useful in applications where the sensor input voltage is noisy or unstable. If the part is ratiometric, an unstable V CC will produce a noisy output.

It is the maximum current draw of the sensor electronics at the specified supply voltage when the primary signal is zero, plus the secondary current IS. This parameter only applies to sensors with current output.

As experience current transducer manufacturer, within 2 months if the customized samples are developed based on the existing product platform. For standard models, it would be 4 to 6 weeks.